Agribusiness Perspectives Papers 1999

Paper 25

ISSN 1442-6951

The Virtually Integrated Enterprise: A Case Study

Improving Customer Service through Logistical Change Management -

Driving Urgency from Supplier to Customer; an integrated approach

Cliff Johnson & Dr Ernst Luthi

August 1999

The Nutritional & Consumer Products sector of Monsanto Australia serviced a wide range of products, from Artificial Sweeteners under the brands of Equal® and NutraSweet® to Home-Use Herbicides, Insecticides, Pesticides and Fertilizers under the brands of Roundup®, Defender® and Phostrogen®. This paper will focus on the initiatives taken by Monsanto Australia in 1998 to drive customer service for Lawn & Garden customers from 39% in 1997 to 98% in 1998. Electronic Data Interchange (EDI) with customers and suppliers, Strategic Supply Partnerships, Warehouse and Transportation Initiatives, External and Internal Cultural Change, Personnel Development and Leadership all combined to created a sense of urgency where the Customer was the Number ONE avenue of meeting sales and profit.

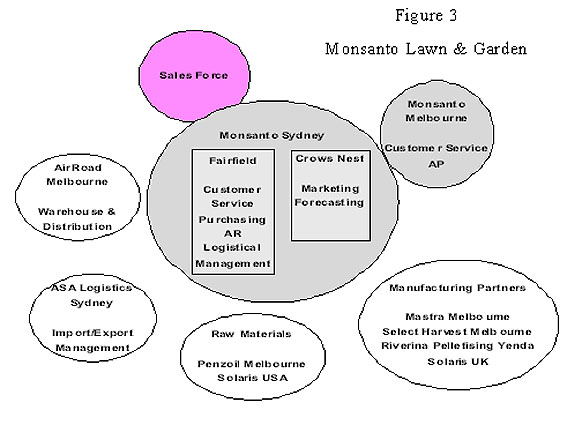

In today's competitive environment, it has become increasingly difficult to achieve excellence in all areas of the supply chain; 1 from customer service to manufacturing and then delivery to the customer. In the traditional model, (see Figure 1) the company is a single unit performing all functions of the supply chain, preferably on the same site.

The planning/purchasing department, through the issue of purchase orders, controls manufacturing or shop orders to internal or external manufacturing. Orders for future needs provided by the company through purchase orders to the external manufacturer might be the only means of the external supplier assessing future requirements. Finished goods are stored at and dispatched from the company's own warehouse either using its own fleet or a distribution company.

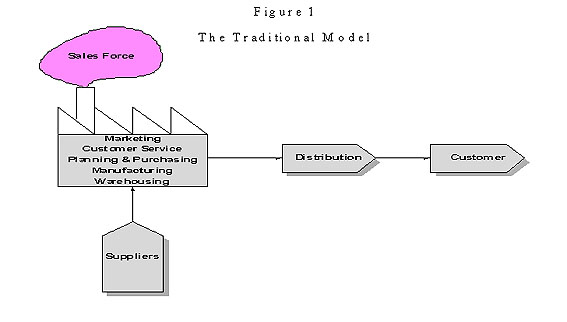

In an attempt to overcome the difficulties in maintaining Best Practice in all areas of the supply chain, companies are becoming more open to outsourcing and forging partnerships with selected third party suppliers 2 . By establishing privileged relations with a few strategic partners who will act as interfaces to all other third parties, a company can control the entire length of the supply chain without losing flexibility.

In the Virtually Integrated Enterprise, manufacturing is still controlled by the planning department; not through the issuing of purchase orders but by providing proactive logistical management and regular information on stock holding and intended stock cover/levels, forecasted demand, forecast accuracy and planned receipts. Based on this information, the manufacturing partners will plan their production to suit the needs of the market and the company. Finished goods are delivered directly to a warehousing/distribution partner who will dispatch the products to the customer based on customer orders processed by the company's customer service.

Partners can be locally situated or be interstate or even overseas. The same applies to the serviced provided by the company where customer service, planning and forecasting and overall coordination can be in different locations, linked together by information technology to a Virtually Integrated Enterprise (see Figure 2.)

Communication

Key Communication between Suppliers, Employees and Customers

Communication is key! It's also paramount, essential, necessary, required, mandatory, and obligatory; the lifeblood of the new millennium - all hackneyed but true. Companies will succeed or fail, wax or wane, progress or regress, by their ability to communicate at an ever-increasing pace and in ever-increasing detail. More so in this technological age than ever before, has communication strategy become an integral part of a company's competitive advantage. Communication is no longer the prerogative of the IT department.

Given perfect communication - every Supply Manager will tell you that materials will be on time and at the best price; every Manufacturing Manager will tell you they will deliver a zero labor variance with optimal machine utilization; every Warehouse Manager will tell you that the customer's order will be picked, packed and delivered on time and in full; every Marketing and Sales Manager will make their number.

We will never have perfect communication! We will never know precisely what our customers want nor will we know precisely when they want it; they don't know themselves! The precept of TQM and Best Practice to meet, anticipate and exceed the customer's expectations is naïve at best; a misleading and ultimately unachievable goal.

Every company knows, or should know, its internal communication needs and channels. The sales department provides feedback to the marketing department who then constructs forecasts for finance and operations. Planning place requirements on manufacturing, who then place requirements on purchasing, who then issue purchase orders on suppliers. The loop closes with the customer placing an order, the finished product delivered and the sale logged. An internal communication loop exists between customer service, planning, the warehouse and manufacturing. This internal loop serves to advise on any internal production or stock problems.

Open orders and backorders are reviewed as new stock enters the system. When a customer calls, the customer service department is able to tell them what stock is available and when it will be delivered. If there is a stock shortage, the customer can be told when it will be available.

The communication needs of the Virtually Integrated Enterprise, as outlined in Figure 2, are not dissimilar. By looking beyond the corporate horizon, by scrubbing away the demarcation lines of legal entities, the needed flows of information can be identified. If your supplier was actually your manufacturing plant, what information would you provide and to whom would you provide it? Ask the same question about your transport companies and customers. Basically, it is an extension of the internal/external customer/supplier relationship analysis of TQM.

It's a pretty safe bet that all companies today use computers in one form or another. Further, it is becoming the norm for companies to have a local network. Multi-site and international companies are finding that Intranet and Internet connections enhance intra-company communication and greatly reduce the difficulty in prying information out of remote sites. Between companies that have regular and frequent contact, EDI or system integration is rapidly replacing the written order. The entry cost of email is dropping every day. Virtually every computer on the market is modem and Internet capable.

What systems are available in your company? Do you have a network? Are your people supplied with PCs? Do they have full suites of software and are they trained? Do you have internal email facilities? Can you access the Internet? Is there a PC in your warehouse and can at least your Warehouse Manager send and receive email? Do your sales force have remote dial in facilities? Ask these questions in your company and ask your customers and suppliers. Can your customers access your systems through the Internet? Can they order products, lodge complaints or send you email? Do your customers have access to your network to check on stock levels, deliveries, order status, etc?

Once you have assessed the technology base of your company, your customers and your partners, then find the common denominator which allows the greatest access to individuals. Avoid the written memo, letter and faxed document. They are too slow and are prone to misplacement; plus, keeping interested parties in the loop with courtesy copies becomes problematic.

We will never have perfect communication! We can, however, perfect our communication and extend it beyond the artificial corporate horizon to the Virtually Integrated Enterprise. Elegant technical solutions are not required. Investing in EDI, LANs and WANs is not absolutely necessary though highly recommended as effective tools. You must select the economically appropriate tool to meet your communication needs.

In the case of Monsanto Australia, in order to allow direct linkage of our communication systems, our partners installed email creating a link between all parts of the supply chain. This took the strategists out of the loop and put action-oriented decision making in the hands of the people we hold accountable for the physical side of the business. Our sales force routinely email our manufacturing partners and our contract warehouse and distribution center for direct and immediate information. This greatly reduced the number of "where is it and how many do we have" phone calls to customer service.

Further, we placed Internet-connected terminals in all internal and external warehouses and trained our customer service personnel in email, business letter writing and spreadsheets. Internal and external staff now deal directly with customers and suppliers and resolve issues before they become problems.

Craft your communication strategy and then resource it fully. You may or may not require capital but you can be sure that you will need to increase your training budget. For example, it is often the case that computer literate order entry staff have no idea how to create a Word document and attach it to an email. How many clerical or customer service staff have ever participated in a conference call? At our Melbourne customer service desk, we will often solve a customer problem with a linked call between sales, the warehouse and manufacturing. One call saves pointless and usually too-late memos which more often than not result in a disappointed customer and start the finger pointing process.

People Development

Achieving the necessary level of communication and behavioral change within and between organizations requires leadership but more importantly, it requires integrity. It is the actual and perceived integrity of the company and its employees that will encourage other third-party companies to join its virtual enterprise and release the natural hesitation of companies to hold their cards close to their chest.

Huge and Park in their article The Best Companies Have the Most Integrity 3 define integrity as ".telling the truth, saying what you're going to do, and doing what you say." (note: this is the essence of ISO9000.) This is critical and cannot be emphasized enough. If your company is not perceived as a company that says what it does and does what it says, you will not be able to create effective communication channels. Effective communication relies upon integrity. The message is filtered through the perceived believability of the sender.

As managers we must provide communication training and business writing skills to our staff and then encourage them to communicate directly with their counterparts in associated companies. We must also provide the information, ability and resources to fix problems. It is a fact of email in the workplace that a significant percentage of the traffic is personal. Set guidelines for your company and provide common sense training. Removing the choke points in corporate communication and non-standard corporate behavior will pay off if managed well.

Step One: Review the job profiles or descriptions for all participants and support staff in your internal supply chain. Is computer literacy required and to what level? Are literacy and mathematics skills required and to what level? Is the ability and willingness to self-direct and self-motivate present? It is likely that you will need to revise positions to reflect a greater level and ability to communicate effectively; to prepare and analyze reports; to conduct meetings; to write memoranda; to solve problems.

Step Two: Evaluate your incumbent personnel. What is the skill gap? What training is needed to bring your staff to the level required by the increased need to communicate effectively? Are your people comfortable with the needs of the Virtually Integrated Enterprise? Are they proactive or reactive; do they have a sense of urgency? Be prepared to invest in people development and training.

Step Three: Listen to your people's problems and recommendations. Encourage them to take responsibility and develop solutions, then support them in implementing them. Involve your people in the decision making process. Provide opportunities to practice the skills. Finally, let go the reins and trust them to do their job. (empowerment?)

Step Four: Be prepared to make the tough decisions. You may have to restructure to bring up some people and to move others along.

Step Five: Expand the people development scheme to the Virtually Integrated Enterprise. Transfer the concept and the philosophy to your partners. Member companies of your virtual enterprise need to conduct the same analysis of their people. All participants in the Virtually Integrated Enterprise must be able to communicate and interact effectively; particularly beyond corporate structures. Form cross-functional and cross-corporate teams outside the conventional boundaries of organizations.

Step Six: Be prepared for mistakes, miscommunication and the occasionally ruffled feather. The individuals and partners will have competing priorities, which can lead to personal tensions. Recognize tensions and assist in addressing and solving the problems.

Recognizing the need for and achieving the reality of partnerships between all links in the supply chain

Strategic Partnerships are the current buzz. Companies do not enter into contractual relationships, they forge alliances. What is needed, however, is to take the next step and fully partner with your ally by transforming the partnership into a Sustainable Virtually Integrated Enterprise. Most partners will see the benefit of closer relationships. Others may require encouragement due to entrenched attitudes and a desire to protect corporate sovereignty.

Successful alliances need:

- Development of a virtual company philosophy and vision on values, sustainability, quality, people development, people empowerment and operational responsibilities;

- Goal alignment, clear definition of tasks and responsibilities;

- Mutual trust, with an open book mentality on market development, cost and expectations, creating win-win situations for all partners to the benefit of the virtual company;

- Breakdown of traditional hierarchical structures with direct, open and free flowing communication; and,

- Strong logistical management geared to identifying, addressing and solving problems, driving the integration and holding the partners together.

At Monsanto Australia, we launched the Virtually Integrated Enterprise at an Operational Logistics Conference, where we brought together a wide selection of people from all levels from our partners and from Monsanto. Running the conference back-to-back with the Lawn & Garden Sales Road Show, gave the attendees a 'live and unplugged' perspective on the 1998 marketing and sales plan for the Lawn & Garden business. By conducting several joint activities between Sales, Marketing, Logistics and Operational attendees, we broke down most, if not all, of the institutional boundaries that had existed in our varied organizations.

We found the main benefit of the conference to be the personal introduction of people who previously had known each other only as printed names and faceless voices. This removed impersonal corporate barriers and made it easier for everybody to initiate communication. We now conduct regular meetings by phone, email, and video link or in person between the people who actually do the doing. Our Sales Representatives now know who the Warehouse and Distribution Manager of our distribution partner is and what he can do for them to make sure that the customer is fully and completely served. Our customer service people met the manufacturing managers of our supply partners and better understand how quickly they can respond to a change in the demand of our products. Our marketing people now know who complains about radically altered sales forecasts.

As an extension to this, we organize regular personal meetings between top and middle management of our partners to discuss problems and to convey our ideas, plans and philosophy.

As with people development, developing partnerships needs time, dedication and strong leadership by the initiating company.

Matching Responsibility with Accountability

In the preceding chapters we talked about the importance of communication, the need to develop employees and the necessity of relationships with our partners in the supply chain. However, to fully explore benefits of these developments, we need to delegate to the lowest possible level, to those people who actually deal with the situation and who know more than anybody else what is happening. We need to manage the business by exception instead of by detail. Blind obedience or "playing it safe" is of no value to the company. At each link in the supply chain, we have to ask ourselves what decision is best for the customer and for the business.

Customer service can be given the authority to manage their customers, which authority is not limited to accepting and processing orders but extends to everything that affects accurate and on-time delivery of orders placed by their customers. They need to know their customers' ordering habits and be able to react to any abnormal order. Customer service needs to be involved in troubleshooting and planning, have authority to deal with customer complaints, pricing issues, returns and claims for credits. If we do not want customer service to be mere order processors but rather order, or better still customer managers, we need to entangle them in any aspect of customer service and assistance.

Warehouse people can be given the authority to manage their own stock holding by calling in stock on an as needed basis, based on a simple signal, such as a reorder point quantity, a free spot in the racking or by comparing actual stock to forecasted requirements. They should also have the authority to question any orders (pick slips) that do not fit into the customer's previous order history.

Distribution will organize delivery of goods to the customer by selecting the best means of transport, ensuring that deadlines are met and then following up on any delays. Customers are informed automatically of any deviations from the schedule and if necessary, alternative means of transport are selected to meet the promised delivery date.

An example of this is our contract warehouse and distribution platform in Melbourne for our Lawn and Garden products. Rather than Monsanto Australia issuing a purchase order each month to supply the warehouse, the Warehouse Manager contacts the contract manufacturer directly by email or telephone and calls up stock as he needs it. Upon the stocks' arrival, the Warehouse Manager books stock into our BPCS system. Each month the Warehouse Manager is sent a 12 month rolling forecast giving current and projected stock positions, anticipated sales and planned receipts from our suppliers as well as 12 month history which provides the basis for his decisions. In case of exceptional sales, the Warehouse Manager alerts the contract manufacturer and Monsanto Australia logistics before a stock out occurs. Alternatively, he may call marketing or planning to assess the need for further stock if he notices a planned production run that might inflate stock levels

In a traditional structure, suppliers or internal manufacturing produce according to plans or purchase orders generated by planning and prioritized by due dates. In our Lawn and Garden business our suppliers of finished goods are integrated in our planning process. They receive each month a 12 month rolling forecast giving current and projected stock positions, anticipated sales and planned receipts as well as 12 month history that forms the basis of our monthly collaborative planning and scheduling meetings. Suppliers have access to our BPCS system and use the information on inventory levels together with the mutually agreed sales and operations plan to prioritize their companies' manufacturing operation.

Delegation of responsibility and people empowerment go hand-in-hand with people training, the definition of company policies, goals and objectives, as well as, an awareness of the limits of authority. There is a need to implement and to agree to clear guidelines and authorities. This is even more important in the Virtually Integrated Enterprise where each individual and each partner need to be aware of their responsibilities and limits. It also requires that people can easily access a source for advice and assistance whenever they feel uncertain, even across company barriers and hierarchical structures. If the decision-maker is not sure, then she/he needs to contact someone for advice.

Customer service personnel will need technical manuals containing information on the products sold, supported by training sessions. Help them to establish a network of contacts they can use to collect additional information or pass inquiries. Outline company policies in regard to pricing, product returns or credit claims; if necessary specified for each customer.

Warehousing staff need a clear definition of stock levels, who their contract partners are, and have to be the first to be informed on any changes to partnerships and agreements.

Distribution requirements need to be defined, such as requirement for proof of delivery, the need to exactly locate any shipment at any time, the importance of speed and cost. Customer Managers need to communicate on a regular basis with dispatchers to ensure that orders are processed and deadlines achieved.

Manufacturing partners need to be aware of the company's customer service philosophy and quality policy to avoid selecting raw material or component supplies of unacceptable quality or producing substandard goods. Manufacturing yields and waste targets need to be defined. Maximal variances in cost of goods should be agreed upon to guide the manufacturer in the selection of raw material sources and when to flag concerns on price variances.

Communication is key in ensuring that authority is used wisely and that boundaries and limits are recognized and redefined as necessary. Partners within the Virtually Integrated Enterprise and individual people managers need to reassure their partners by issuing regular reports on their actions and gathering the information needed to recognize and correct any overuse of authority detrimental to the common goal.

To support the concept of supply chain empowerment, measurements should be established which assist all members, internally and across the Virtually Integrated Enterprise, in aligning themselves with the common goal. These key performance indicators (KPIs) provide the basis to determine individual and team success and overall progress. KPIs established within the Virtually Integrated Enterprise need to be compatible with those defined by the individual partners. There may be a need for an overall set of performance measures to align the individual components to the common goal.

Key performance indicators should clearly define the objective of all processes, address the critical success factors, outline actual measures and set performance targets to be measured and benchmarked. Individual and overall team performance needs to be monitored routinely and the results fed back to the team on a regular basis to assist in the constant improvement process.

If the overall objective of empowering the supply chain is to improve customer service, increase velocity and reduced cost, then KPIs should be:

- Balanced between those main objectives and across the supply/manufacture, warehousing and dispatch and customer service functions;

- Compatible with the KPIs set by individual partners within the vertically integrated enterprise;

- Limited to a manageable number (usually 10 - 15);

- Meaningful and kept simple and easy to measure;

- Clearly establish responsibilities; and,

- Designed so that outcomes support and drive change in behavior.

Identify KPIs across the Virtually Integrated Enterprise

Customer service measurements could comprise of measuring a number of orders processed on time, in full and correctly, the number of customer inquiries and complaints handled and solved successfully within a set timeframe. It should also include a measure of the customers' satisfaction with the Customer Manager based on feedback obtained from selected customers.

Warehousing and distribution KPIs should focus on accuracy of stock levels, timely call up of goods, accuracy of order picking, shipment on time, in full and to the correct location, the time needed to track orders, cost of transport, feedback from transport partners and customers.

Manufacturers and suppliers will be measured against their ability to deliver the quantity requested on time and in the quality required, their ability to contribute to cost reductions and product improvement.

KPIs for the Virtually Integrated Enterprise should look at the velocity of information flow, the speed at which exceptions are managed, the overall cost savings benefiting all partners, and cross-functional/cross-company teamwork.

Transforming the Supply Chain

Communication, People Development, Strategic Partnerships, Empowering the Supply chain all come together in creating the Sustainable Virtually Integrated Enterprise as outlined in Table 1.

Table 1:

|

Transform

|

From

|

To

|

|

Customer service

|

Order Entry Clerks

|

Order/Customer Managers

|

|

Warehouse

|

Moving Cartons & Barrels

|

Inventory level and Supplier Managers

|

|

Distribution

|

Putting cartons & barrels on trucks

|

Selecting means of transport to suit customer

|

|

Manufacturer/Supplier

|

Producing to order

|

Collaborative planning and scheduling based on forecast and history.

|

|

Conglomerate of independent companies

|

Corporate self interest

|

The Sustainable Virtually Integrated Enterprise - a network of partners striving towards the same long term goal

|

Urgent Customer Service

"As a life sciences company, we are committed to finding solutions to the growing global needs for food and health by sharing common forms of science and technology among agriculture, nutrition and health. The company's 21,000 employees worldwide make and market high-value agricultural products, pharmaceuticals and food ingredients." 4 The Lawn & Garden business of the Nutritional and Consumer Products Sector of Monsanto was developed through taking the Agricultural product Roundup® to the retail and consumer market and through acquisition of home-use pesticide and fertilizer brands; building what was prior to it's sale, a US $500 Million business worldwide.

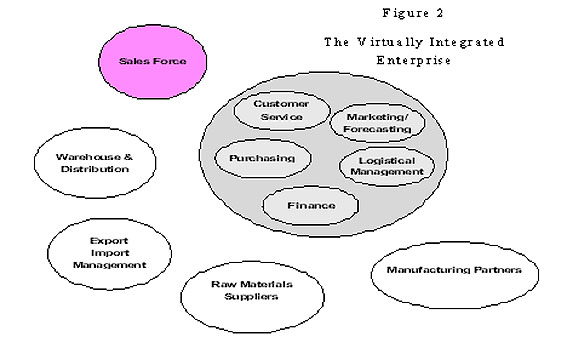

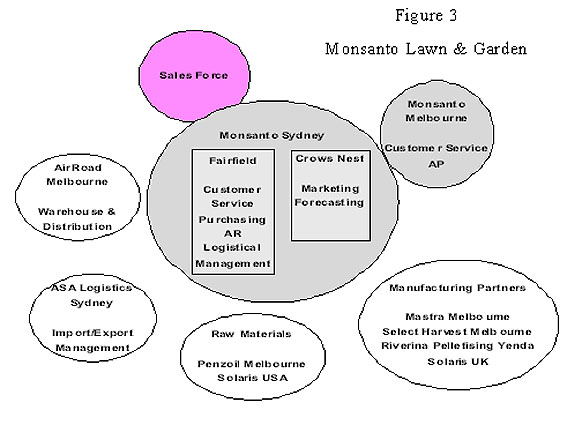

The Australian Monsanto N&CP Lawn & Garden business was a true Virtually Integrated Enterprise, see Figure 3. Literally, it did not exist. We did not manufacture. Third party manufacturers in the UK, Yenda and Melbourne produced our products. We had no warehouse; our product was held and distributed by AirRoad Logistical SupportT. Our customer service department resided in the Melbourne Monsanto Agricultural Head Office and in the Sydney Nutritional & Consumer Products Factory; virtually centralized through linked computers and toll-free numbers. Our sales force and marketing department was run out of Sydney by the Consumer division of Monsanto Australia who, before Lawn & Garden, sold and marketed only Equal® and NutraSweet®.

Monsanto Australia Lawn & Garden circa 1997

During the three-month Spring season, Lawn & Garden companies traditionally sell 70% of their annual volume. In a masterstroke of brilliant planning, Monsanto N&CP Australia acquired the Phostrogen® brand in January and the Defender® brand in April; three months before pre-season production for Spring 1997 was to commence. No transition was available. (To be fair, the opportunity was there and needed to be grasped.) No internal liquid, dust or pellets manufacturing facilities were available in Australia. The Monsanto Australia Agricultural Sector (Monsanto Ag) operates a Roundup manufacturing and packaging facility in Melbourne. However, the demand for broad-acre bulk packaged Roundup® was increasing and without substantial investment the Roundup® factory was not suitable for retail packaging of herbicides and pesticides.

The warehousing and distribution company used by Monsanto Australia Ag specialized in the storage and transport of industrial bulk hazardous goods. Lacking alternatives and seeing the potential for synergies, Monsanto Australia N&CP joined Ag at their contract warehouse. However, the picking and packing of small cartons, filling small orders and delivering to small retail outlets as required by Monsanto N & CP Lawn & Garden was not the core business for Ag's contract warehouse company and they were unable to meet the customer service levels required by the retail market.

The season began with a whimper, primarily from the sales force. Most products were out of stock or in short supply as Mastra, our toll manufacturer of retail Roundup® came to grips with the onslaught of forty new and urgent products. The overseas supplier of Phostrogen® had recently been acquired and had lost its entire logistics and export staff. Ten containers of product arrived jumbled and severely damaged. It seems that nobody remained that understood the quality of packaging and palletizing that sea transport required. . Adding insult to injury, the newly appointed Australian Lawn & Garden product manager misread the product catalogue and the quantities were wrong; 26-years worth of Phostrogen® Feed & Spray sets arrived.

Customer complaints began. Wrong product, damaged product, wrong quantity, and wrong delivery. The favorite example given by survivors of 1997 was the two pallets delivered to the parking lot of Woolworth's head office. Admittedly, the delivery was on time and in full but.

Monsanto Australia Lawn & Garden circa 1998

Something had to change. But what? We had to develop and document systems and procedures; drive urgency from supplier to customer - we had to have the right amount of the right stock delivered undamaged to the right location. We:

-

First examined where our stock was being held, how much visibility and control we had, and how much confidence we had in the picking and packing; not to mention distribution, of our customers' orders. Stock had been held in each state of Australia and in New Zealand. The first step was to consolidate the stocks in Melbourne. Control was the primary, not cost. We transitioned from our previous warehouse and transportation provider to AirRoad Logistical Support (ARLS.) This was completed in six-weeks during peak season. All stock was secured and counted on site at AirRoad. Inventory adjustments from physical count to book quantities were made and procedures implemented to reconcile inventory to physical each month. ARLS is a small-to-medium-sized logistics and transport company that focuses on the customer. They barcode each shipment and track it from the moment it leaves the warehouse to the moment it arrives at the customer. Proof of Delivery is available via the Internet or immediately

via a telephone call. Our desire in the market place was to use customer service as a competitive advantage; ARLS supported this.

-

Created and published a Monsanto N&CP Customer Service Manual. This enables employees with average computer literacy to accept and process an order, receive and manage stock and solve customer problems. It also provided a base to standardize customer service across two locations (Sydney/Melbourne).

-

Created and published a Monsanto N&CP Technical Information Manual. This manual was designed to give the reader adequate knowledge and information to answer customer inquiries about the contents, active ingredients, pallet and carton quantities, and the use and hazards of our Lawn & Garden products. Copies of the manual have been provided to all Sales Representatives and customer service personnel.

-

Virtually centralized customer service in Melbourne with customer service in Fairfield. This was accomplished through EDI linkages and toll-free FAX and telephone lines. Where the call was answered was transparent to the customer. All customer service personnel have been cross-trained in all products. Previously, we had separate Lawn & Garden, Searle Pharmaceutical and Equal order processing; we had no backup or depth of resource in any product line. Customer Service Representatives meet in person every two months to discuss common issues. They are in contact daily by telephone and email.

-

Combined all N&CP Logistical Management functions. Proactively managed internal and external warehouses to improve performance and reduce cost. Implemented cycle counting, regular housekeeping and performance management through key performance indicators. Active transition of Material Manager's responsibilities whilst decreasing headcount. Management of Planning function and upskilling of personnel as needed. We focused on team building and communication channels.

-

Creation and management of effective Sales & Operations planning for Lawn & Garden production. Management of monthly SOP reviews, inventory levels and supplier communication. Proactive management of manufacturing partners with regular meetings or telephone conferences to create a "we belong to the same company feeling."

The result? Service Levels improved from 39% to 98% through customer focussed management of Distribution & Manufacturing partners and customer service personnel. Customer complaints for damaged, short or non-delivery reduced to minimal levels. We brought Urgency into the supply chain. If every step from order receipt to delivery is treated as an urgent matter, panic and fire fighting will be a thing of the unlamented past.

The horizontal Virtually Integrated Enterprise

Sharing resources to maximize infrastructure performance - Beating the Big Boys with a Virtual Merger

The future is here!

Above we have described a process that can best be described as a vertical Virtually Integrated Enterprise. This concept can be applied within all markets and within all countries; the larger the business and the larger the market, the greater the opportunities for virtual integration. Virtual Vertical Manufacturing 5, its precursor, is already here and is being applied; within Monsanto and elsewhere in the world.

However, particularly in a small market such as Australia, the future may lie in an extension of the concept; to a horizontal Virtually Integrated Enterprise. Sharing the infrastructure of another like but non-competitor organization can give the economies of scale only available to major corporations; in effect, it creates a virtual merger.

The hypothetical horizontally virtually integrated companies sell similar but non-competitive products through the same channels to the same customers. By horizontally integrating these companies and extending the IT, Purchasing, Logistics, Warehousing, Distribution and Sales structure, virtually merged companies can improve net income substantially whilst improving customer service.

Strategic Management

Creating the Virtual Company requires a new Breed of Managers and Employees

According to Epstein (1998),

"The company of the future will consist of a small team running its affairs from a single office. The team will build and use its knowledge of market demands and customer requirements, potential suppliers and partners and bring them together through sophisticated electronic links to respond quickly and painlessly to changes in fashion and economic circumstance. The process of creating value will be set free from all unnecessary activities, and for that reason alone will be significantly more efficient".

Virtual integration instead of vertical integration will be the driver of the future. However, can virtuality, the ultimate result of total strategic outsourcing, be successful and achieved without a major business paradigm change? Can we successfully manage the transition from the industrial age to the virtual age without a new breed of managers and employees?

Definition of a virtual company

Smolowitz (1997) defines a virtual corporation as a "company that relies on outsourcing or the use of outside resources to deliver products and services. Malone & Davidow (1992) talk of a metacorporation, extending upwards to its suppliers and downwards through distribution to the customer. The virtual company will focus on its core competencies and draw on a network of external relationships to conduct its business. It will leverage the investments each element of the metacorporation has made to achieve a higher degree of competency than would have been possible on its own.

Benefits of going virtual

The benefits of becoming a virtual company and outsource non-core competencies are various:

-

Sharpened business focus: management focuses on broader business issues and serving the customer by outsourcing operational details to outside experts

-

Access to world-class capabilities and resources: Leveraging on investments made by partner companies

-

Freeing resources for more strategic activities: Less individual investment in human resources, fixed assets or development time, sharing risks

-

Increased profitability and improved business processes: By partnering with highly efficient and profitable companies

-

Manufacturing flexibility: Possibility to react to changes in manufacturing capacity quickly and to turn out new products faster

-

Overall flexibility: Possibility to react to technological progress and changing customer needs by changing partners or extending partner base

(Dunn, 1999; Christie & Levary 1998; Corbett, 1998; Magretta, 1998)

Overall, the corporation ends up with more capabilities and power than it inherently possesses, increasing its potential and competitive advantage (Christie & Levary, 1998). Combining world-class competencies in the virtual company provides "the means to meet customers' needs faster and more efficiently ... and to be "more responsive to change." (Michael Dell in Magretta, 1998).

Current trends

Strategic outsourcing is widespread (Irvine, 1998; Smolowitz, 1995). Outsourcing occurs mostly in administrative and support functions, like training, payroll, human resource management and IT management (Mariotti, 1999; Garner, 1998; Asbrand, 1997; DeRose & McLaughlin. 1995). However, in recent years more and more companies have started outsourcing value-creating activities such as manufacturing, logistics or marketing in a move to concentrate on core competencies only (Mariotti, 1999; Brown, 1997; Rheem, 1997; Anonymous, 1995a; Anonymous, 1995b; Semler, 1993).

According to Corbett (1998), US $ 100 billion was spent on outsourced services in 1996 in the US alone and this will grow to US $ 300 billion by 2001. And outsourcing seems to be successful, with companies reporting an average of 9 % savings in functions that were outsourced (Crump, 1997). However, for many companies, outsourcing is not working. Brown (1997) reports that only 5 % of 300 companies investigated found outsourcing high on benefits and low on drawbacks. For many outsourcing was either mediocre or a flop.

So, what differentiates virtual corporations, like Dell Computer, Ford Motor Company, IBM (Magretta, 1998; Smolowitz, 1997), Boeing, Nike, Gallo (Irvine, 1998) and Semco (Semler, 1993), that succeed from those that fail?

Success factors

The following factors have been identified to contribute to the success of virtual corporations:

-

Long term objectives: Strategic long-term and integrated perspective

-

Careful selection of partners with right core competencies: Create synergies and win-win situations

-

Clear definition of goals and outcomes: Goal alignment, clear definition of tasks and responsibilities

-

Communication and information: Free flow of information across hierarchies and companies backed up by integrated technological resources

-

Mutual trust on all levels: Trust in capabilities and abilities of management, employees and partners. Open book policy

-

People: Right abilities and behaviours, strong leadership and relationship management skills

-

New kind of organisational structure: Breakdown of traditional hierarchies inside and across companies.

-

Development of a virtual company philosophy and culture shared by all partners

Christie & Levary, 1998; Garner, 1998; Laabs, 1993;

Working in a virtual company will turn current assumptions on work and management upside down. Virtuality requires changes in the attitudes of managers and employees, types of control and reward systems, company secrecy and loyalty to the company (Christie & Levary, 1998; Cohen, 1997; Crandall & Wallace, 1997; Malone & Davidow, 1992).

Decisions have to be made by keeping the benefit of the virtual company in mind on not just the employing company. Company affiliation as such will become irrelevant, as tasks will be carried out in cross-company teams that may change daily. Trust and empowerment, - intra- and inter-company -, self-direction and the ability to make decisions and judgements based on the demands of a specific situation become more important. Efficient communication, coordination and relationship management will become paramount for success. The ability to manage and work in networks of people may be as key to the future success as the core competencies of the partners involved in a virtual company.

Thus, for the move from the industrial age to the virtual age to be successful, we need a new understanding of business and a new breed of leaders and employees. We need a clearly defined outsourcing strategy and we need people that understand the concepts of partnership, relationship building and trust to turn the strategy into a success.6

Bibliography

Anonymous, 1995a. "Virtual companies, real profits". Nation's Business, Vol 83, n 12, p21.

Anonymous, 1995b. "GM's partner in time". Traffic Management, Vol 34, no 47, p47-48.

Asbrand, D, 1997. "Outsourcing becomes strategic" Datamation, Vol 43, No 7, p. 73.

Brown, M, 1997. " Outsourcery". Management Today, January 1997, p56-60.

Christie, PMJ, Levary, R, 1998. "Virtual corporations: Recipe for success". Industrial Management, Vol 40, no 4, p. 7-11.

Cohen, S, 1997. "On becoming virtual". Training & Development, Vol 51, no 5, p. 30-37.

Corbett, MF, 1998. "Outsourcing: Beyond buying services". Facility Design & Management, Vol 17, no 1, p.40-43.

Crandall NF & Wallace Jr, MJ, 1997. "Inside the virtual workplace: Forging a new deal for work and rewards" Compensation and Benefits Review, Vol 29, no 1, p. 27-36.

Crump, JG, 1997. "Strategic Alliances fit pattern of industry innovation". TheOil and Gas Journal, Vol 95, no 13, p. 59-61.

DeRose, GJ & McLaughlin, 1995. "Outsourcing through partnership". Training and Development, Vol 49, no 10, p. 51-55.

Dunn, RL, 1999. "Exploring outsourcing". Plant Engineering, Vol 53, no 3, p. 123-129.

Epstein, JH, 1998. "The relationship economy". The Futurist, Vol 32, no 8, p. 8-9.

Garner, R, 1998. "Strategic outsourcing: It's your move". Datamation, Vol 44, no 2, p. 32-41.

Irvine, J. 1998. "Onwards and outwards". Accountancy, Vol 122, no 1264, p. 46-47.

Laabs, JJ, 1993. "Successful outsourcing depends on critical factors" Personnel Journal, Vol 72, no 10, p. 51-56.

Magretta, J, 1998. "The power of virtual integration: An interview with Dell Computer's Michael Dell". Harvard Business Review, Vol 76, no 2, p. 72-84.

Malone, M & Davidow, D, 1992. "Virtual corporation" Forbes, Vol 150, no13, p. 102-107.

Mariotti, J, 1999. "Strategic outsourcing can be powerful medicine". Industry week, Vol 248, No 8, p.58.

Rheem, H, 1997. "Logistics: A trend continues". Harvard Business Review, Vol 75, no 1, p. 8-9.

Semler, R, 1993. "Maverick !" Arrow Business Books. ISBN 0 09 932941 7.

Smolowitz, I, 1997. "The future of American corporations". Business Forum, Vol 22, no 2-3, p.73.

Endnotes

1 - C Jutras, ERM, Vol 2, June 1998, p 24. Restructuring the supply chain through VVM

2 - E Polastro, Manuf Chem, May 1997, p 36-37. A shared vision for solving manufacturing problems.

3 - Huge et al, Target Innovation at Work, Volume 14, Number 3, Third Quarter 1998, p26-30.

4 - Monsanto Company 1997 Annual Report,

5 - Jurtas, Conference Proceedings of the APICS 1998 International Conference. Virtually Vertical Manufacturing - Transforming the Supply Chain, p93-107.

6 - The same principles apply to "virtual", or internal outsourcing, where departments (eg. marketing, logistics, warehousing, etc) are set up as individual units competing internally and externally for work. The role of senior management is to define the company direction and manage the individual units to achieve set outcomes.

|